Additional EMC Test Equipment

New Equipment for Radiated Immunity Testing

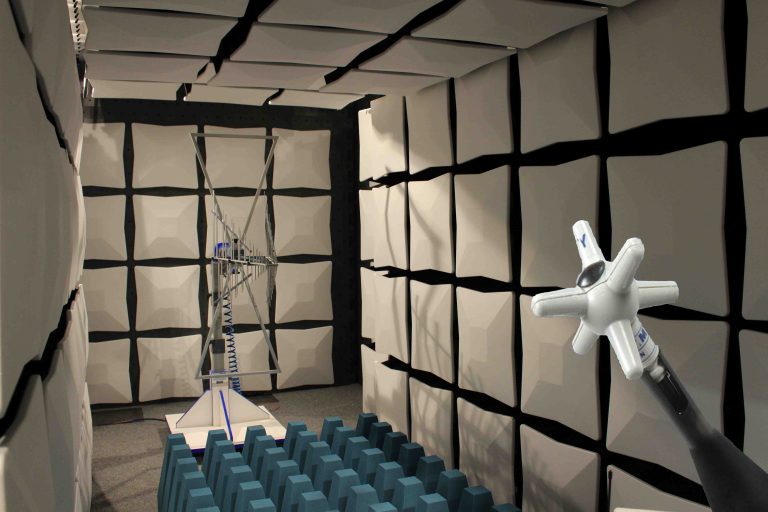

The Mission Embedded EMC Lab is now even better equipped. In addition to emissions tests, we can now also conduct electromagnetic immunity testing, further extending Mission Embedded’s range of EMC-related services. Our customers and partners continue to benefit from up-to-date testing equipment for their pre-compliance tests during development.

Electromagnetic immunity, in addition to emitted interference, plays a key role in the device approval process due to its indication of the degree with which a system or device is capable of resisting against an interference source, i.e., how much interference radiation a device can withstand without malfunctions or service disruptions. This capacity can be determined via tests utilizing frequency and impulse generators, as well as RF amplifiers, in an EMC test chamber.

Electromagnetic immunity testing:

- Frequency spectrum: up to 1 GHz

- Generated interference: up to 30 V/m

- Performance (continuous output): 300 W

Immunity – Knowledge and Know-how

Electromagnetic interference (EMI) can result in the malfunction and disruption of service in almost all electronic system components, especially integrated circuits. Special attention has to be paid to the electromagnetic immunity of safety-critical applications, such as railway (EN 50121-3-2), air traffic control (EUROCAE ED-14), medical technology (DIN EN/IEC 60601-1-2) and military applications (MIL-STD 461) etc. In the EU, the legislation stipulates particular protective requirements that must be met when introducing electrical equipment into the market.

Respective limit values for interference immunity (as well as for emitted interference) are standardized in, for example, EN 61000-6, EN 55024 CISPR 24, EN 61000-4-2. While norms and regulations are already rather complex inside the EU, product approval and certification become even more challenging in the international market. Our experts are happy to provide support and and answer all questions regarding EMC testing and certifications.

Testing During Development – Early Bird Catches the Mistake

It is important to conduct radiated immunity tests during the development phase (pre-compliance), as malfunctions can result in significant impacts on the device design. The earlier a fault is detected, the sooner (and with fewer expenses) corresponding changes can be made. These during-development tests can now be fully automated in our EMC Lab. With its state-of-the-art test equipment, Mission Embedded’s EMC Lab takes a leading role in the pre-compliance domain.

Are you interested in our EMC services?

Contact us now and make an appointment with our experts: sales@mission-embedded.com.