Into the future with Smart Machines & AI

Smart Machines & AI: From Sci-Fi to your Product

Why You Need AI & Machine Learning

Smart machines are capable of decision making and problem solving without human intervention. The key is artificial intelligence (AI) and machine learning. In machine learning, a so-called self-learning algorithm is taught to recognize patterns and rules using training data. Smart machines often have machine-to-machine (M2M) communication capabilities, meaning they can communicate directly with other machines and devices. The implementation of smart sensor systems allows for the processing of information about the environment. These concepts are becoming increasingly mainstream and can already be found in everyday products- from cars to washing machines. Today, more and more companies utilize smart machines to optimize their processes.

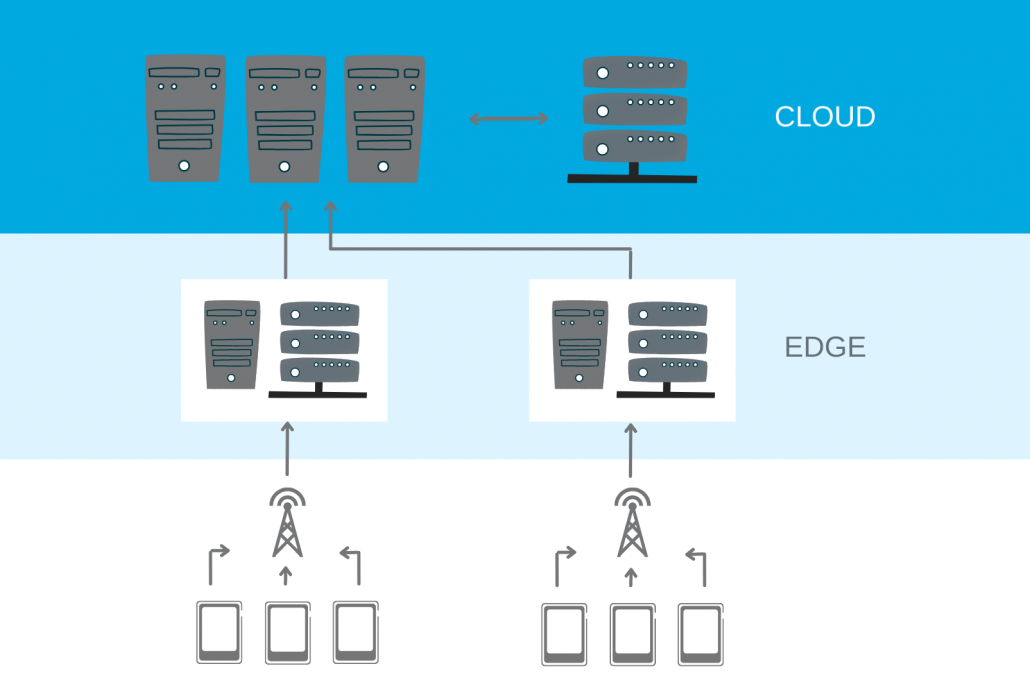

State of the Art: Cloud vs. Edge Computing

The complex computing processes necessary for AI and machine learning applications require the appropriate infrastructure. Established solutions usually utilize either a cloud based service or on-site computing centers, both of which use centralized computing power. In offline applications for industrial environments, these centralized systems can quickly reach their limits as their computing power is finite. A more advanced alternative, Edge Computing, pushes data processing towards the edges of the network and closer to the data consuming devices. Edge computing thus reduces both the volume of data needing to be transferred and the data latency, thereby helping to avoid bottlenecks and improving the performance of real-time and wireless applications.

Data-driven Development and Smart Machines

Systems that use multimodal sensor systems and artificial intelligence cannot be planned entirely “on the drawing board”. Data needs to be collected in the real field of application, which is in turn used to train the artificial intelligence. This brings new challenges for traditional development processes. Mission Embedded provides high-performance platforms for the efficient data collection and effective testing of neural networks in industrial applications.

Outline of the Typical AI Project with Mission Embedded

The typical digitization project starts with a specific problem brought forth by the customer. For the implementation of intelligent sensors and artificial intelligence experienced experts are needed. Mission Embedded analyses the requirements and evaluates if a traditional algorithmic approach or AI best addresses the specific problem. Frequently, the optimal solution is a combination of both. An example of this project approach is our assistance systems based on camera systems.

Fast-Cost Proof of Concept with Flexible ME Platforms

The next step is the proof of concept. As often times existing ME software can be used, costs are able to be kept low. Agile software development allows for the rapid adaptions to changing customer requirements. For field testing, an existing ME Vision & Machine Learning Platform is integrated into the costumer product. During this step, very limited training data is required.

Data Acquisition Campaign

Using the ME platform for data acquisition, data is gathered during field operation and automatically uploaded via 4G/LTE. Data labeling and AI training takes place in the cloud and can be carried out either by the customer or by Mission Embedded.

Development of Functionalities

At the same time, new functionality is continuously integrated and delivered, with updated software being downloaded remotely onto the ME Platform. The full functionality of the system is demonstrated on the ME Platform, followed by field testing and an acceptance analysis by the customer.

Rapid Industrialization and Cost Optimization for the Specific Application

Turnaround times for the industrialization can be kept short, as a large portion of the software development has already been completed. The development of tailor-made hardware ready for series production as well as the integration of the already functional software, usually takes between four and seven months.